Investment casting, also known as lost wax casting, is a manufacturing process in which a wax pattern is created and then coated with a ceramic slurry to create a mold. The wax is then melted out of the ceramic mold and molten metal is poured into the ceramic mold cavity. The molten metal solidifies and the ceramic shell is then broken or blasted off, creating a metal casting. The investment casting process does not require a minimum order quantity and can cast parts ranging from a few ounces to upwards of 200 kgs, so it can be a manufacturing solution no matter what size project you are working on.

Investment casting offers several advantages, including the ability to produce complex shapes with high accuracy, excellent surface finishes, and the capability to use a wide range of metals and alloys. It's commonly used in industries such as Aerospace, Automotive, Oil & Gas, General Engineering, Medical Equipment manufacturing and others Industries.

Investment casting, also known as lost-wax casting, is a manufacturing process used to create complex geometry of metal parts with high precision and intricate details. Here's how it works:

Simulates the casting process in advance, eliminating multiple trials and achieving high quality at the first time.

Read More

Automated to produce patterns efficiently and provide dimensionally consistent patterns.

Read More

The process begins with the creation of a pattern, which is a replica of the desired part. This pattern can be made from wax material. It's usually made using a mold or by machining.

Read More

Multiple patterns may be assembled onto a central wax gating system, forming a cluster known as the "tree." This gating system allows for the flow of molten metal into the cavity created by the pattern.

Read More

The process begins with the creation of a pattern, which is a replica of the desired part. This pattern can be made from wax material. It's usually made using a mold or by machining.

Read More

The process begins with the creation of a pattern, which is a replica of the desired part. This pattern can be made from wax material. It's usually made using a mold or by machining.

Read More

The process begins with the creation of a pattern, which is a replica of the desired part. This pattern can be made from wax material. It's usually made using a mold or by machining.

Read More

Molten metal is poured into the cavity left by the pattern. The metal fills the space, taking on the exact shape and details of the original pattern.

Read More

Molten metal is poured into the cavity left by the pattern. The metal fills the space, taking on the exact shape and details of the original pattern.

Read More

Molten metal is poured into the cavity left by the pattern. The metal fills the space, taking on the exact shape and details of the original pattern.

Read More

Molten metal is poured into the cavity left by the pattern. The metal fills the space, taking on the exact shape and details of the original pattern.

Read More

Molten metal is poured into the cavity left by the pattern. The metal fills the space, taking on the exact shape and details of the original pattern.

Read MoreThe advantages of investment casting are impressive. Create almost any configuration of your precision metal component with High Dimensional Accurcy and Superior surface finishing at very compitative cost. A Design parts as small, large, or complex as you need. In short, eliminate many of the barriers holding you back today.

Consider the following investment casting benefits, which can also help you:

Tool steel is a type of alloy steel known for its hardness, wear resistance, and ability to maintain its shape at high temperatures, making it ideal for various tooling applications. It's used in the manufacturing of tools for cutting, shaping, and forming materials, including both metal and non-metal.

400 series stainless steels are known for their high strength, hardness, and magnetic properties, making them suitable for various applications, including automotive parts, and industrial equipment. It is also used in some construction and medical applications and General Engineering.

Aluminum investment casting is used across numerous industries for producing complex, high-precision parts. Applications range from aerospace and automotive components to medical devices and consumer goods, leveraging aluminum's lightweight, strong, and corrosion-resistant properties.

Carbon steel primarily consists of iron and carbon, while low alloy steel includes additional elements like manganese, nickel, chromium, and molybdenum to enhance specific properties. Low alloy steels generally offer higher strength, improved weldability, and better corrosion resistance compared to carbon steels.

Cobalt-based alloys are used in a wide range of applications due to their unique combination of properties, including high strength, wear resistance, corrosion resistance, and high-temperature stability. This is commonly found in aerospace, medical, and industrial applications.

Nickel-based alloys are used in a wide range of applications due to their high strength, corrosion resistance, and ability to withstand high temperatures. These alloys are crucial in industries like aerospace, chemical processing, and power generation, among others.

Thermal expansion alloys are used in a wide range of applications where maintaining dimensional stability across varying temperatures is crucial. These alloys, often nickel-iron based, are used in electronics, aerospace, precision instruments, and more, where their controlled thermal expansion properties prevent warping, cracking, or other issues caused by temperature changes.

Stainless steel is a family of iron-based alloys known for their corrosion and heat resistance. Key properties include high strength, durability, resistance to corrosion and high temperatures, ease of formability, and low maintenance requirements.

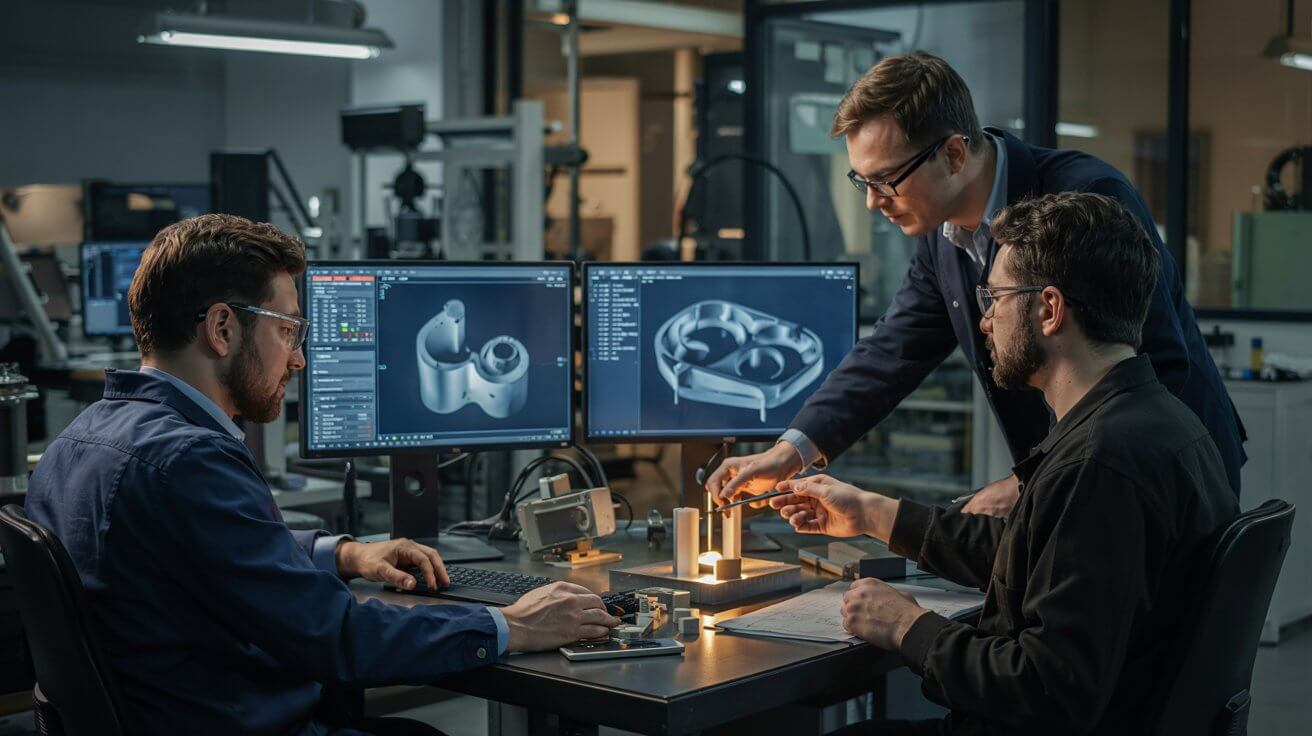

By definition, a prototype is the first, preliminary model that allows design engineers the ability to quickly and efficiently explore their designs, test their performance, and craft even better components. After all, production components will be modeled and copied from this initial part.

When the prototype is the building block essential to the success of a project, don’t be forced to choose a prototyping supplier based on time and cost. So much can be learned from a prototype’s function, the need for a quality prototype is critical. When designing metal components, an exact replica of your final part is the best prototype you can get.

Crunch time may mean different things for different projects, but one thing’s for sure, nobody wants unforeseen surprises.

Stopping to prototype your design, evaluate its feasibility, and ensure its productivity might be critical to your product’s ultimate success. But at this stage of a product’s lifecycle, timing is essential. A delay of weeks can result in lower sales and lost market share.

Our in-house rapid prototyping can significantly accelerate your time-to-market. We simulate production using the specific process and our proprietary wax to deliver the most accurate results at a fraction of the time it takes other investment casting companies.

When it comes to developing your ideas, we’ve got the most effective prototyping options for your component—not to mention the in-house prototyping experts to help you choose the right one for the job. Our prototyping capabilities include:

Rajhans does not have a minimum order quantity for prototypes. So whether you need one or one hundred, our team can provide a consistent supply of production-like components.

Best of all, we can create prototypes in as little as five days. Our average tooling lead time is three to five days. Lead times can vary based on complexity of the part and overall project needs.

We know that finding a supplier who can constantly and consistently supply prototypes can make or break your business. Investment cast prototyping is efficient in the overall cost and time of the project. The best thing is, you do not have to compromise quality for time or cost. Our in-house team of knowledgeable engineers are constantly thinking outside of the box to ensure our customer’s designs become a successful reality. Let us help you succeed.