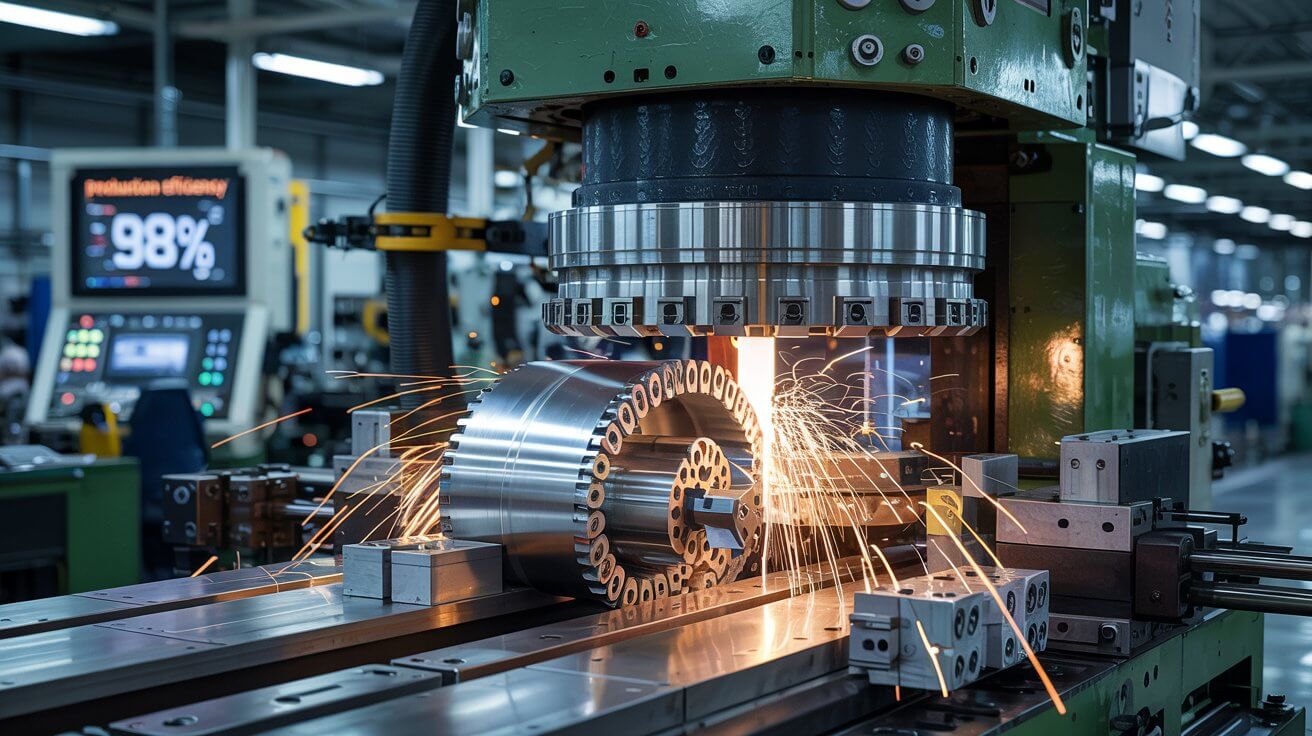

Metal stamping is a manufacturing process used to convert flat metal sheets into specific shapes using a combination of punching, blanking, bending, and other forming techniques. It is widely employed in various engineering fields due to its efficiency, precision, and ability to produce high-volume parts.

Investment casting, also known as lost-wax casting, is a manufacturing process used to create complex geometry of metal parts with high precision and intricate details. Here's how it works:

The first step involves designing the part and creating the necessary tooling (dies). Dies are typically made from hardened steel and are precision-machined to match the desired part geometry.

Read More

Metal sheets or coils are selected based on the required material properties and thickness. These sheets are fed into the stamping press.

Read More

The stamping press, equipped with the designed dies, applies force to shape the metal. Common stamping operations include:

Blanking: Cutting a flat piece (blank) from the metal sheet.

Punching: Creating holes or cutouts in the sheet.

Bending: Forming the sheet into a specific angle or shape.

Drawing: Stretching the sheet into a three-dimensional shape.

Coining: Impressing detailed features onto the sheet.

Depending on the complexity of the part, multiple stamping operations may be required. The formed parts may be assembled, welded, or joined as needed.

Read More

The stamped parts may undergo additional processes such as deburring, painting, coating, or plating to enhance their appearance and durability.

Read MoreThe advantages of investment casting are impressive. Create almost any configuration of your precision metal component with High Dimensional Accurcy and Superior surface finishing at very compitative cost. A Design parts as small, large, or complex as you need. In short, eliminate many of the barriers holding you back today.

Consider the following investment casting benefits, which can also help you:

Rajhans makes tools from alloys of iron containing 0.25-2.5% carbon with substantial amounts of chromium, molybdenum, tungsten, vanadium, cobalt, and to a lesser extent nickel to achieve the desired combination of hardenability, hardness, toughness, and wear resistance.

The 400-series group of stainless steels contain 11-27% chromium, up to about 1% carbon, and 2.5% nickel maximum. The grades of stainless steel castings Rajhans most often produces respond to heat treatment and can be supplied with a predominantly martensitic microstructure in a wide range of strength and hardness.

Aluminum alloys possess a unique combination of mechanical properties and corrosion resistance. These alloys are roughly one-third as dense as steel with higher strength to weight ratios.

Carbon and low alloy steels are the workhorses of the mechanical world. No other class of materials offers as wide a range of mechanical properties as economically.

Cobalt based alloys are very corrosion and heat resistant due, in large part, to the unique properties of cobalt. The alloys produced at Rajhans are generally for heat resistance and/or wear resistance and therefore contain large amounts of carbon, chromium, and carbide formers like tungsten.

Consisting primarily of nickel, chromium, and molybdenum, smaller additions of other alloying elements are used to create alloys with very high corrosion resistance while other elements would be used to create alloys with very high hot strength.

Thermal expansion alloys, such as Invar and Kovar, are made up of an iron-nickel base and are known for their low coefficient of thermal expansion (CTE). Iron and nickel have very similar CTE, however with these alloys, thermal expansion is affected by the addition of nickel to iron.

The 300-series group of stainless steels contain 16-30% chromium and from 6-35% nickel. Depending on the composition, the microstructure is predominantly or wholly austenitic and thus unresponsive to heat treatment.

By definition, a prototype is the first, preliminary model that allows design engineers the ability to quickly and efficiently explore their designs, test their performance, and craft even better components. After all, production components will be modeled and copied from this initial part.

When the prototype is the building block essential to the success of a project, don’t be forced to choose a prototyping supplier based on time and cost. So much can be learned from a prototype’s function, the need for a quality prototype is critical. When designing metal components, an exact replica of your final part is the best prototype you can get.

Crunch time may mean different things for different projects, but one thing’s for sure, nobody wants unforeseen surprises.

Stopping to prototype your design, evaluate its feasibility, and ensure its productivity might be critical to your product’s ultimate success. But at this stage of a product’s lifecycle, timing is essential. A delay of weeks can result in lower sales and lost market share.

Our in-house rapid prototyping can significantly accelerate your time-to-market. We simulate production using the specific process and our proprietary wax to deliver the most accurate results at a fraction of the time it takes other investment casting companies.

When it comes to developing your ideas, we’ve got the most effective prototyping options for your component—not to mention the in-house prototyping experts to help you choose the right one for the job. Our prototyping capabilities include:

Rajhans does not have a minimum order quantity for prototypes. So whether you need one or one hundred, our team can provide a consistent supply of production-like components.

Best of all, we can create prototypes in as little as five days. Our average tooling lead time is three to five days. Lead times can vary based on complexity of the part and overall project needs.

We know that finding a supplier who can constantly and consistently supply prototypes can make or break your business. Investment cast prototyping is efficient in the overall cost and time of the project. The best thing is, you do not have to compromise quality for time or cost. Our in-house team of knowledgeable engineers are constantly thinking outside of the box to ensure our customer’s designs become a successful reality. Let us help you succeed.