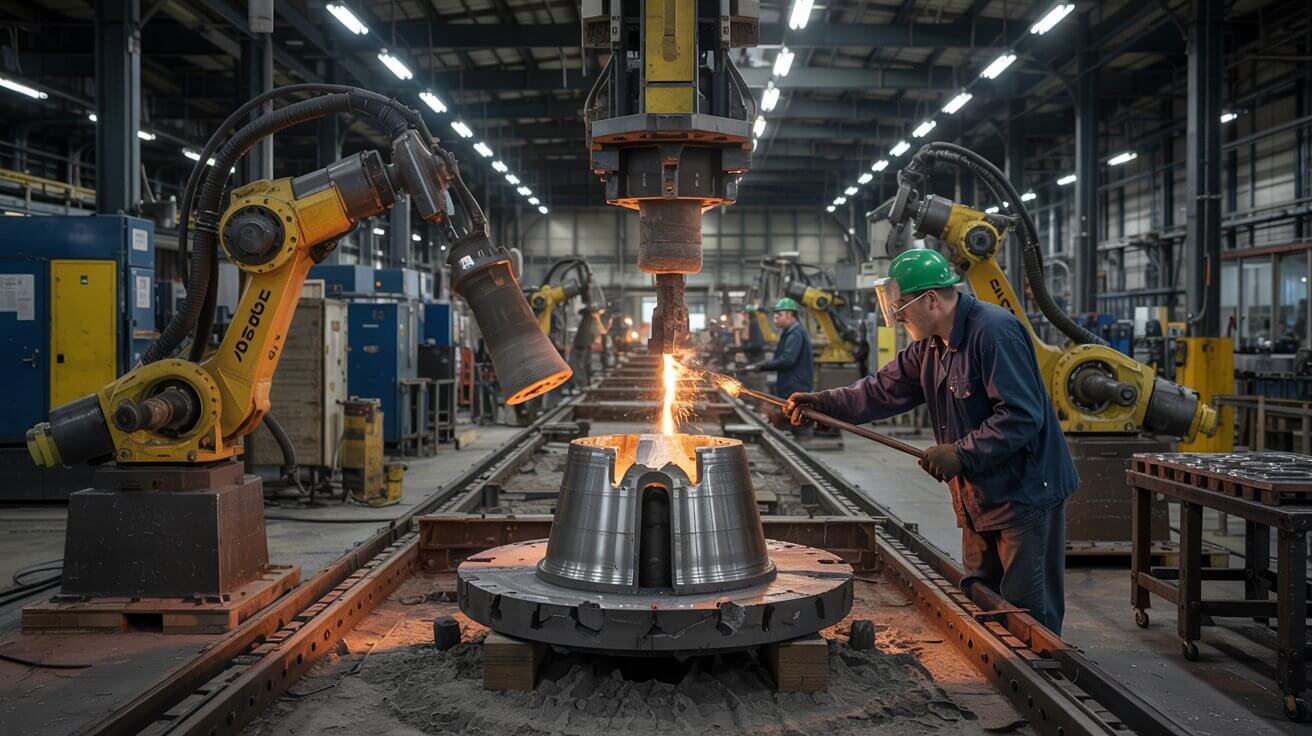

Metal casting is the process in which molten metal is poured into a mold and allowed to solidify into an object. The object that solidifies is called a casting. Sand casting is defined as pouring of molten metal into a sand mold and allowing it to solidify in the mold. Sand casting is the most widely used metal casting process in manufacturing and almost all casting metals can be sand cast. A few examples of modern items manufactured by the sand casting processes are gears, dies used in the general components, cylinder heads, pump housings, and valves components. The Sand casting parts ranging from a few ounces to upwards of 1000 kgs, so it can be a manufacturing solution no matter what size project you are working on.

Sand casting is commonly used for producing large, complex parts in materials such as iron, steel, aluminum, and bronze. It's relatively inexpensive and can accommodate a wide range of part sizes and shapes, making it a popular choice in the manufacturing industry.

Investment casting, also known as lost-wax casting, is a manufacturing process used to create complex geometry of metal parts with high precision and intricate details. Here's how it works:

Simulates the casting process in advance, eliminating multiple trials and achieving high quality at the first time.

Read More

A pattern of the desired part is created using wood or metal. This pattern is a replica of the final part and is used to create the mold.

Read More

The pattern is placed in a box or flask and surrounded by molding sand. The sand is typically a mixture of silica sand, clay, and water. The sand is packed tightly around the pattern to create the mold cavity.

Read More

Once the sand has set, the pattern is removed from the mold, leaving behind a cavity in the shape of the desired part.

Read More

If the part requires internal features or hollow sections, cores made of sand or metal may be inserted into the mold cavity.

Read More

If the part is complex and requires multiple pieces, the mold is assembled by placing the cope (top half) and drag (bottom half) together. Channels called sprues, runners, and gates are also formed in the sand to allow the molten metal to flow into the mold cavity.

Read More

Molten metal is poured into the mold cavity through the sprue. The metal fills the cavity and takes the shape of the part.

Read More

Once the metal has solidified, the sand mold is broken apart to reveal the metal casting inside.

Read More

The casting may undergo various finishing processes such as grinding, sandblasting, machining, or heat treatment to achieve the final desired shape, surface finish, and mechanical properties.

Read MoreThe advantages of investment casting are impressive. Create almost any configuration of your precision metal component with High Dimensional Accurcy and Superior surface finishing at very compitative cost. A Design parts as small, large, or complex as you need. In short, eliminate many of the barriers holding you back today.

Consider the following investment casting benefits, which can also help you:

Ductile iron, also known as nodular or spheroidal graphite iron, is a type of cast iron with enhanced properties compared to traditional gray cast iron. It achieves this improved strength, flexibility, and impact resistance due to its unique graphite microstructure, where the graphite is formed into spherical nodules rather than flakes.

Gray cast iron is a type of cast iron characterized by its graphite flakes, which give it a gray color on a fractured surface. It's a widely used engineering material due to its good machinability, damping capacity, and relatively low cost.

Carbon steel primarily consists of iron and carbon, while low alloy steel includes additional elements like manganese, nickel, chromium, and molybdenum to enhance specific properties. Low alloy steels generally offer higher strength, improved weldability, and better corrosion resistance compared to carbon steels.

Stainless steel is a family of iron-based alloys known for their corrosion and heat resistance. Key properties include high strength, durability, resistance to corrosion and high temperatures, ease of formability, and low maintenance requirements.

By definition, a prototype is the first, preliminary model that allows design engineers the ability to quickly and efficiently explore their designs, test their performance, and craft even better components. After all, production components will be modeled and copied from this initial part.

When the prototype is the building block essential to the success of a project, don’t be forced to choose a prototyping supplier based on time and cost. So much can be learned from a prototype’s function, the need for a quality prototype is critical. When designing metal components, an exact replica of your final part is the best prototype you can get.

Crunch time may mean different things for different projects, but one thing’s for sure, nobody wants unforeseen surprises.

Stopping to prototype your design, evaluate its feasibility, and ensure its productivity might be critical to your product’s ultimate success. But at this stage of a product’s lifecycle, timing is essential. A delay of weeks can result in lower sales and lost market share.

Our in-house rapid prototyping can significantly accelerate your time-to-market. We simulate production using the specific process and our proprietary wax to deliver the most accurate results at a fraction of the time it takes other investment casting companies.

When it comes to developing your ideas, we’ve got the most effective prototyping options for your component—not to mention the in-house prototyping experts to help you choose the right one for the job. Our prototyping capabilities include:

Rajhans does not have a minimum order quantity for prototypes. So whether you need one or one hundred, our team can provide a consistent supply of production-like components.

Best of all, we can create prototypes in as little as five days. Our average tooling lead time is three to five days. Lead times can vary based on complexity of the part and overall project needs.

We know that finding a supplier who can constantly and consistently supply prototypes can make or break your business. Investment cast prototyping is efficient in the overall cost and time of the project. The best thing is, you do not have to compromise quality for time or cost. Our in-house team of knowledgeable engineers are constantly thinking outside of the box to ensure our customer’s designs become a successful reality. Let us help you succeed.